Road Markings put to Abrasion Test

The line markings on our roads are exposed to mechanical, climatic and chemical forces every day. A recent field study reveals why material selection and maintenance are crucial factors that determine more than just high visibility.

Lane markings are the clearly visible conductors of road traffic - they enable all kinds of road users to move safely and in an organised manner within the same space. However, these vital aids to orientation are subject to constant wear and tear. Failing to maintain and renew road markings on time can have serious consequences – both for road safety and for the environment. A recent study has clearly shown that if markings are used beyond their functional service life, not only does the risk of accidents increase, but so does microplastic exposure.

Visually identify wear and tear

How much do road markings actually wear down under heavy use? And how much microplastic could be expected from road markings exposed to heavy traffic? Tomasz E. Burghardt from the Centre of Competence – the globally interconnected research department of SWARCO Road Marking Systems – and Anton Pashkevich from the Technical University of Krakow investigated these questions. As part of a joint field study, the experts examined three busy zebra crossings in Poland. Their goal was to systematically record the degree of abrasion of different road marking materials in relation to traffic volume and to draw specific conclusions for environmental and safety aspects.

Cold Plastic

faded Cold Plastic after 3 years

Paint

faded Paint after 3 years

The right choice of material is crucial

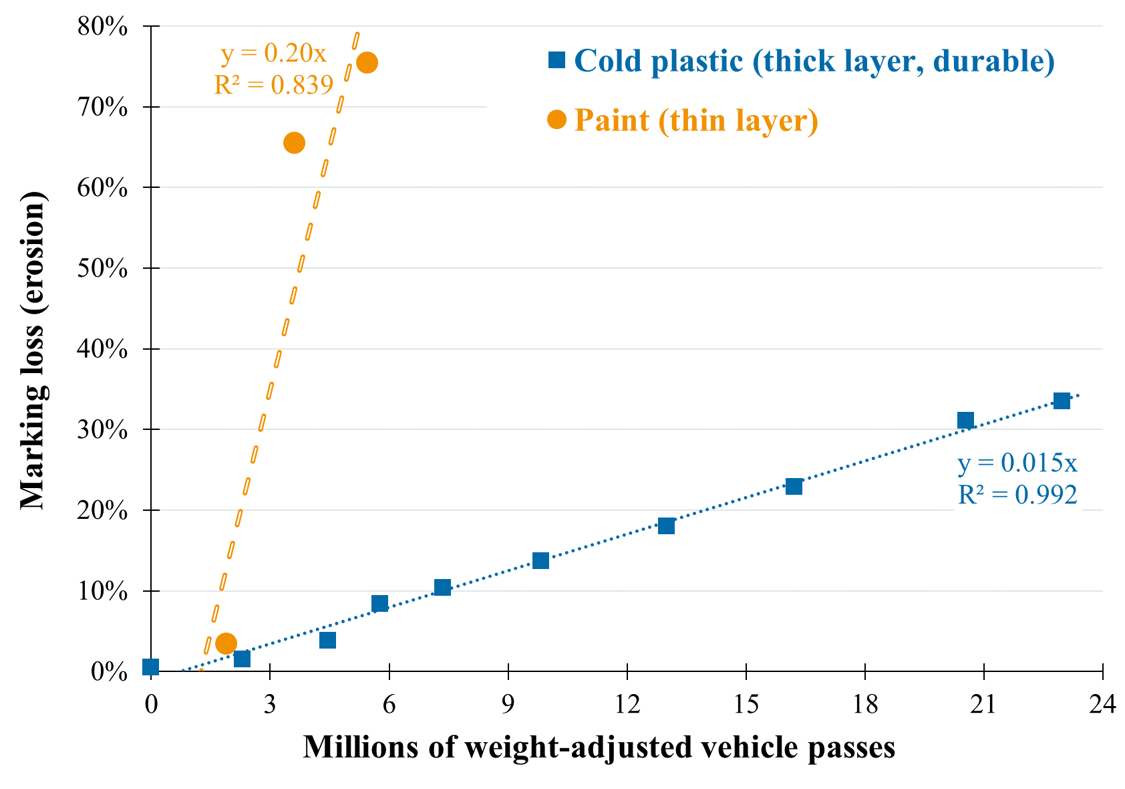

For three years, Burghardt and Pashkevich examined the abrasion on the selected pedestrian crossings along the busy Droga krajowa 2 (National Road 2) in Poland. Two of the crosswalks examined were marked with textured cold plastic, while the third was initially marked with paint. This difference turned out to be significant, as the results are clear: the cold plastic showed only 1.4 to 1.8% loss per one million of weight-adjusted vehicles per lane (MWAVL), while the paint marking lost over 20%. The abrasion on the heavily trafficked areas of the zebra crossing was particularly noticeable, where 97% of the paint markings had disappeared after only one year. It was hardly surprising that the paint wore off so quickly – after all, the material is designed for edge markings, not for high-traffic areas such as pedestrian crossings.

How much microplastic is emitted?

Based on the abrasion determined, the researchers were also able to calculate the amount of microplastics released. “We assumed that cold plastic has a polymer content of 20.5% and that consumption is 3.5 kg/m²,” explains Tomasz Burghardt. “For paint, on the other hand, the application rate is only 0.6 kg/m² and the assumed polymer content is also significantly lower at 12%.”

If these values are now linked with the observed material losses, the resulting picture is as follows: With cold plastic, this corresponds to 10.3 to 12.9 g/m² of estimated polymer emissions per one million of weight-adjusted vehicles per lane. For paint, the value was significantly higher at 14.5 g/m², despite a lower polymer content and a much thinner layer.

Significant improvement

The observations at the pedestrian crossing originally marked with paint could only be carried out for one year. Subsequently, this crossing was also marked with cold plastic. The result: the recorded marking loss was significantly reduced and was in line with the level of the other two zebra crossings. However, the markings were renewed at a later date – this time apparently with inferior material or poorly executed. As a result, wear increased noticeably again and deviated significantly from the values previously achieved.

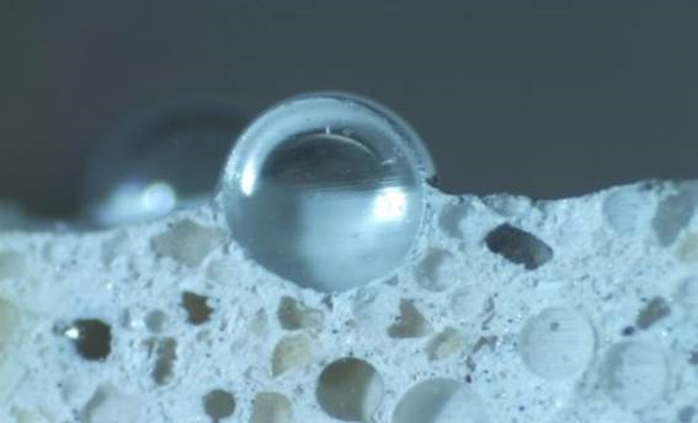

The data from the field study clearly emphasises that choosing the right marking material is essential and must be tailored to the traffic load and place of use. In the scenario examined, structured cold plastic lane markings impressed with their high abrasion resistance. In combination with reflective glass beads, they are also highly visible in the dark and wet conditions.

Dual advantage with reflective glass beads

These glass beads do double duty: on the one hand, they improve visibility in difficult lighting conditions through retro-reflection, which significantly increases road safety. On the other hand, they form a protective layer that protects the underlying marking material from excessive wear. This reduces marking intervals and costs and can also prevent the release of microplastic particles. However, this is only possible if the markings are applied professionally with the right material and renewed on time. Clearly defined maintenance schedules for road markings are therefore essential to ensure the safety of road users and the environment alike.

A closer look at the study

Objective: To provide reliable data for environmental and transport experts and infrastructure operators on microplastic emissions from road markings under real traffic conditions.

Duration: 3 years

Test objects: Three pedestrian crossings on a busy national road in Poland (between Kałuszyn and Siedlce), two of which were initially marked with structured cold plastic and a zebra crossing marked with paint.

Measurement method:

- Images of the markings were taken regularly over a period of three years.

- The loss of luminance (brightness) served as an indirect measure of abrasion.

- The number of vehicles was taken into account on a weight basis (MWAVL = 1 million of weight-adjusted vehicles per lane).

- Microplastic emissions were calculated based on material consumption (cold plastic: 3.5 kg/m²; paint: 0.6 kg/m²) and material composition (polymer content in cold plastic: 20.5%, in paint: 12%).

Results at a glance

Material | Average Marking Loss / MWAVL | Microplastic Emissions / MWAVL |

|---|---|---|

Cold Plastic | 1.4 - 1.8% | 10.3 - 12.9g |

Paint | 20.2% | 14.5g |

If the choice of material is key: What different materials can be used for road markings?

Road markings can be roughly divided into water- and solvent-based paints, thermoplastic and cold plastics, thermoplastic spray, cold spray plastics, preformed thermoplastic, prefabricated cold plastics, and tapes.

However, there are also differences within these material groups that are important for application: for example, there are 1-component and multi-component cold plastics, each of these materials requires completely different equipment.

How do microplastics originate from road markings?

After a protective layer of retroreflective glass beads are lost, abrasion causes fine particles of polymer components to become detached – especially if markings are used beyond their functional service life and do not get renewed.

Can microplastic emissions from road markings be avoided?

Not entirely, but the release can be significantly reduced by choosing the right material, applying it correctly and replacing it before the functional service life has ended.

How often do road markings need to be renewed?

This depends on various factors such as the material used, the road surface, the traffic load and also the prevailing climatic conditions.

What role do reflective glass beads play in the service life of markings?

The micro glass beads are primarily used for night-time visibility through retroreflection, but as drop-on beads they also form a protective layer that provides additional resistance to abrasion.

What does SWARCO recommend based on this study?

We recommend using high-quality marking materials and properly matched reflective glass beads. This avoids unnecessary extra work for re-marking and more frequent maintenance. Clear maintenance schedules should also be put in place to ensure road markings maintain their functional properties.

About SWARCO Road Marking Systems

Quality products and services from SWARCO Road Marking Systems guide traffic safely from A to B by day and, above all, by night. On all types of roads. Whatever the weather. From a single source. Over 5,000 customers in more than 80 countries place their trust in them.