Performance, Well Beyond 12 Million Wheel Passes

12 Million Wheel Passes: A New Benchmark

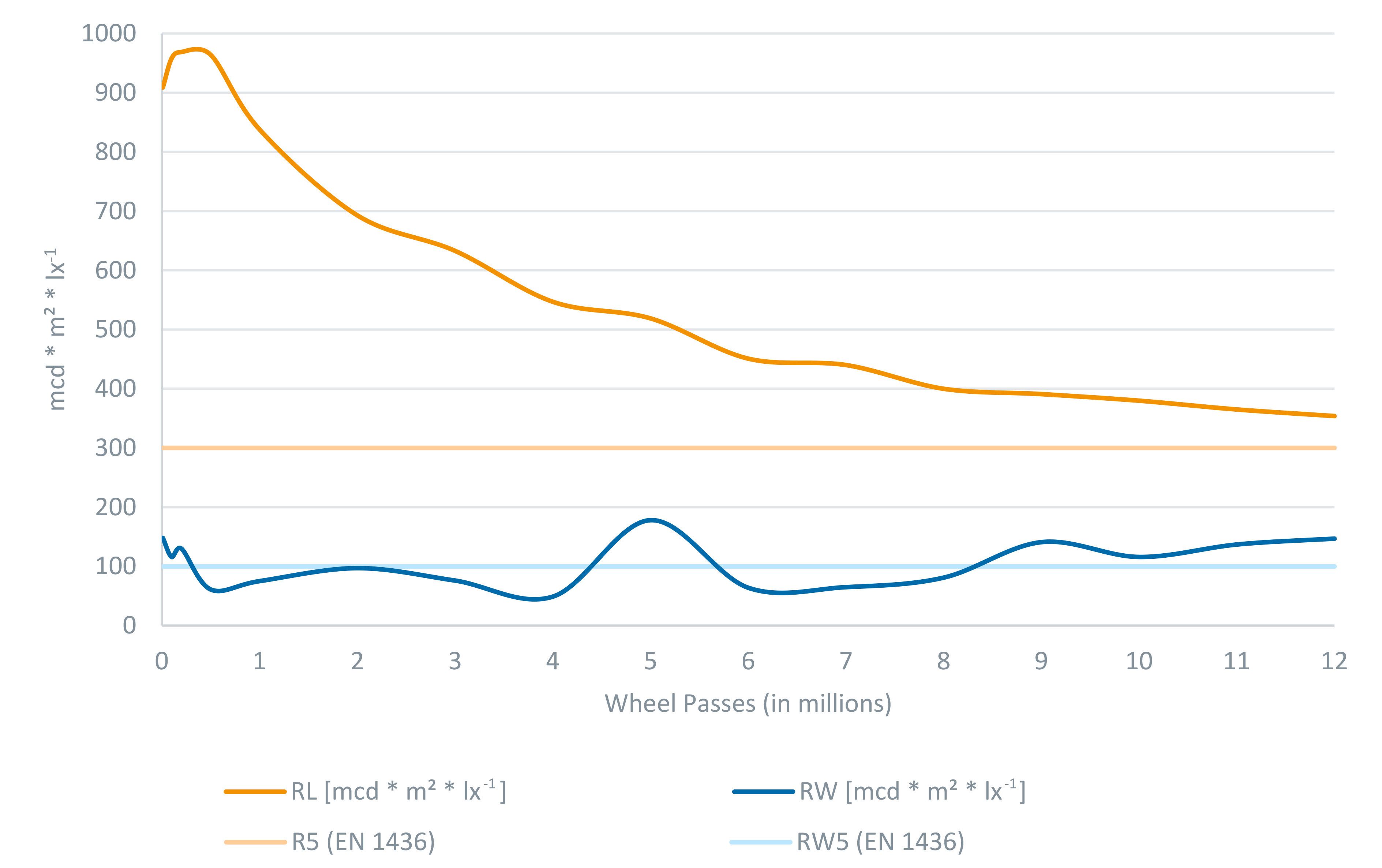

SWARCO set out to quantify this precisely. At the Federal Highway Research Institute in Germany (BASt), a SWARCO marking system underwent a rigorous endurance test on BASt’s rotary traffic simulator (Rundlaufprüfanlage, RPA). Specifically, SWARCOPLAST G601—an MMA-based cold plastic system combined with SWARCO SOLIDPLUS reflective glass beads—was assessed for visibility, pushing far beyond the currently highest requirement of 4 million simulated wheel passes. In fact, the test tripled that threshold.

The result: Even after 12 million simulated wheel passes, retroreflectivity values remained clearly above the thresholds for the highest classes of EN 1436—for both agglomerate markings and full lines. This puts the MMA-based system in a class of its own. As Mario Nöllge, Managing Director at SWARCO’s Diez site, emphasizes: “No other marking system of this type has previously achieved such outstanding long-term performance. The key is the premix glass beads, which—used for the first time in a cold-plastic full-line system—deliver excellent retroreflection over such an extended period.” Detailed measurements for a 3 mm full-line marking show:

| Initial | 4 million | 12 million | |

| RL [mcd * m² * lx^-1] | 909 | 547 | 354 |

| RW [mcd * m² * lx^-1] | 148 | 49 | 147 |

Proven Long-Term Performance

Why do the values remain so high? In short, because the marking material and micro glass beads are engineered to work together as a high-performance system. SWARCOPLAST G601, with its high whiteness, provides a solid foundation. The drop-on beads remain securely embedded in the MMA cold plastic for a long time. Controlled, gentle wear gradually exposes the premix beads within the material—without damaging them. The result is sustained retroreflection, even under heavy traffic and winter maintenance.

Mario Nöllge underscores the importance of product quality: “Achieving these retroreflectivity levels after so many wheel passes requires premium raw materials—from the methacrylate resin and titanium dioxide pigment to our SWARCO SOLIDPLUS glass beads.”

Due to their specially engineered glass composition, SWARCO SOLIDPLUS reflective beads also deliver exceptional durability. Numerous field applications have shown that these premium beads withstand mechanical loads far better than standard beads. In combination with other high-grade system components (MMA binder, titanium dioxide, etc.), their back-reflection performance can be maintained at a high level over the long term.

Why Consistent Visibility Matters

Safety gains come from consistency, not just peak values—and that is precisely what the measurements confirm. Standards and guidelines—such as the Manual on Uniform Traffic Control Devices (MUTCD) in the United States—define minimum values, for example an RL of 50 or 100

mcd⋅m^(2)⋅lx^(−1) depending on posted speed limits. Similarly, EN 1436 provides a clear performance framework for road markings.

Accordingly, road authorities seek high-quality markings that reliably meet these levels under sustained loads and over long periods. That’s why valid data is crucial: SWARCOPLAST G601 markings demonstrate reserves even after massive mechanical stress from millions of wheel passes. For road authorities and road operators, this translates into longer maintenance intervals, predictable life-cycle costs, fewer work zones, and reduced material usage—without compromising safety.

What’s Next?

The results to date clearly show that markings made with SWARCOPLAST G601 and SWARCO SOLIDPLUS glass bead technology remain visible for a long time. For SWARCO Road Marking Systems, this is not the finish line. Where others are satisfied, we want to learn more, test further, and keep improving. We are therefore continuing the investigations systematically—even under extreme conditions and well beyond 12 million wheel passes. Real road safety is built not on assumptions, but on knowledge, precision, and continuous innovation.

FAQ

mcd⋅m^2⋅lx^−1. High, stable values enhance lane perception, curve guidance, and forward visibility at junctions over extended periods—helping reduce steering and braking errors, especially at night.

These premium reflective beads use a specially engineered glass formulation that combines a high refractive index with outstanding robustness. This enables excellent retroreflectivity and reduces bead loss under heavy traffic—delivering a double benefit for long-term marking visibility.